Workplace Safety Procedures That Actually Work in NZ

Understanding What The Law Actually Expects From You

Let's be honest, diving into legal acts and regulations can feel like trying to read a foreign language. When you see something like the Health and Safety at Work Act 2015 (HSWA), it’s easy to get overwhelmed. But what does the law really expect from you as a business owner or manager in New Zealand? It boils down to one core idea: taking all reasonably practicable steps to ensure the health and safety of your workers. This doesn't mean you have to create a completely risk-free bubble—that's impossible. It means you must proactively manage the risks you can actually control.

The term you’ll see everywhere is PCBU, which stands for a 'person conducting a business or undertaking'. This is a broad term that covers almost everyone in charge, from a large construction company to a sole trader who hires a subcontractor. As a PCBU, your primary duty of care is to your workers, but it also extends to visitors, customers, and anyone else who might be affected by your work. This is where many businesses get tangled up—they either do too little, hoping for the best, or they overcomplicate things with mountains of useless paperwork. The key is finding a practical middle ground that genuinely keeps people safe.

The Non-Negotiables vs. Good Practice

So, what’s the difference between a legal must-do and something that’s just a good idea? The non-negotiables under HSWA involve actively identifying workplace hazards, assessing the associated risks, and putting effective controls in place. For instance, if you run a manufacturing plant, providing machine guarding isn't just a good idea; it's a fundamental requirement. Similarly, ensuring your team has and uses the right personal protective equipment (PPE) is a non-negotiable obligation.

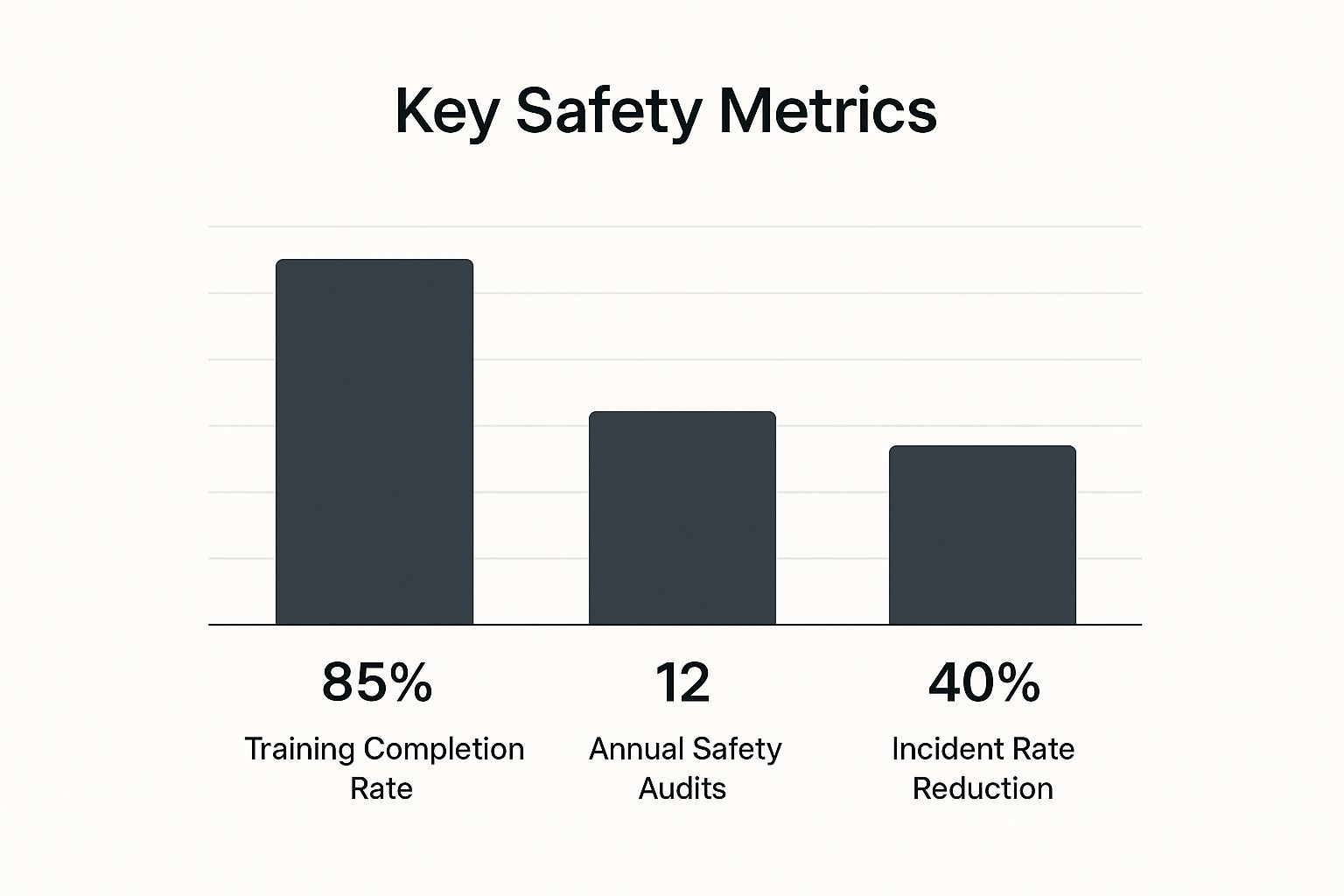

On the other hand, "good practice" might be something like investing in ergonomic office chairs. While it contributes to worker wellbeing and is a great idea, it falls into a different category than failing to address a frayed electrical cord on a piece of machinery. The most successful businesses are those that not only meet their core obligations but also thoughtfully adopt good practices. This creates a culture where safety is simply part of how things are done. The following chart highlights some key metrics that reflect a business actively managing its safety commitments.

These figures show how consistent effort in training and auditing can lead to a significant 40% reduction in incidents, a clear indicator of effective workplace safety procedures.

Navigating WorkSafe and Compliance

WorkSafe NZ is the country's main regulator, and understanding their approach can clarify your responsibilities. While some might view WorkSafe inspections as a threat, their real goal is to ensure businesses are fulfilling their duties. Interestingly, New Zealand's enforcement landscape has some unique characteristics compared to our neighbours across the ditch.

To give you a clearer picture, here’s a breakdown of how safety enforcement compares between New Zealand and Australia.

| Enforcement Aspect | New Zealand | Australia | Impact on Compliance |

|---|---|---|---|

| Primary Regulator | WorkSafe NZ | State-based regulators (e.g., SafeWork NSW, WorkSafe Victoria) | Businesses in Australia need to navigate state-specific rules, while NZ has one national body. |

| Inspection Focus | Often reactive, responding to incidents or complaints. Proactive inspections are less frequent. | A stronger emphasis on proactive, unannounced site inspections and industry-wide blitzes. | The lower frequency of proactive checks in NZ means businesses must be more self-reliant on their internal safety systems. |

| Penalty Structure | Penalties can be severe, especially for serious breaches, relative to the economy's size. | Fines and penalties are also substantial but are part of a more visible, preventative enforcement model. | The high-consequence model in NZ makes getting it right from the start critical to avoid significant financial and legal trouble. |

| Guidance & Resources | Provides extensive guidance, but the onus is on the PCBU to interpret and apply it. | Regulators often issue very prescriptive codes of practice and targeted campaigns. | Australian businesses may find compliance more clear-cut, while NZ businesses need to actively seek out and understand their obligations. |

This comparison shows a focus on consequence rather than prevention in New Zealand's approach, making it even more crucial for businesses to get their internal workplace safety procedures right from the start. You can read the full analysis of NZ's enforcement approach for a deeper look. To stay ahead, it's vital to know which specific safety regulations apply to your industry. You can learn more about these critical industry-specific safety standards in our detailed guide.

Risk Assessments That Uncover Real Dangers

A truly effective approach to workplace safety procedures starts long before you write a single rule. It begins with a risk assessment, but not the kind that involves ticking boxes on a generic, downloaded template. A meaningful assessment digs deep to uncover the real dangers in your specific environment—the ones that often get overlooked until it's too late.

Think of it like a detective investigating a scene before a crime has even happened. Your goal is to spot the clues that point to potential harm, not just list the obvious culprits.

This shift in mindset, from a compliance task to a discovery mission, is what separates a risk assessment that collects dust from one that becomes a living document guiding daily decisions. The reality is that injuries still happen with alarming frequency. In 2023, New Zealand saw a total of 226,600 work-related injury claims, a slight increase from the previous year. This figure shows the ongoing challenges, especially in high-risk sectors like agriculture, manufacturing, and construction. A reactive approach simply isn’t enough; you must be proactive. For a closer look at these national trends, you can explore the complete 2023 work-related injury statistics.

Getting Your Team Genuinely Involved

One of the biggest mistakes businesses make is conducting risk assessments from the manager's office. The people who operate the machinery, walk the factory floor, or drive the delivery routes every day have a perspective you can't get from a desk. They know which corner is a blind spot, which piece of equipment has a subtle but worrying vibration, and which process forces them into an awkward, repetitive posture.

Your job is to create an environment where they feel safe and encouraged to share this vital knowledge. Instead of a formal meeting, try a more casual "walk-and-talk" approach. Grab a couple of your frontline team members and walk through their typical workday, asking open-ended questions like:

- "What's the most frustrating part of this task?"

- "Is there anything you have to rig up or work around to get the job done?"

- "If you could change one thing about this area to make it safer, what would it be?"

This method turns a top-down instruction into a collaborative effort. Workers are more likely to buy into the resulting workplace safety procedures because they had a hand in creating them. They see it as a genuine attempt to protect them, not just another administrative hurdle.

Documenting and Prioritising Risks

Once you've gathered this on-the-ground intelligence, the next challenge is organising it in a way that makes sense to everyone. A complex matrix filled with jargon is only useful to a safety officer. A simple, visual system is far more effective for the entire team. A great way to do this is with a risk prioritisation table that clearly outlines what you've found and what you plan to do about it.

To put this into perspective, here’s a look at some of the high-risk industries in New Zealand and the common dangers they face.

Work-Related Injury Claims by Industry Sector

Breakdown of New Zealand workplace injury statistics by high-risk industries

| Industry Sector | Injury Claims | Risk Level | Common Hazards |

|---|---|---|---|

| Agriculture & Forestry | 22,200 | Severe | Vehicle rollovers, machinery entanglement, exposure to chemicals, fatigue during peak seasons. |

| Construction | 28,100 | Severe | Falls from height, trench collapses, being struck by moving objects or vehicles, silica dust exposure. |

| Manufacturing | 24,900 | High | Machine guarding failures, manual handling injuries, noise-induced hearing loss, forklift incidents. |

| Transport & Logistics | 13,800 | High | Driver fatigue, loading/unloading injuries, musculoskeletal strain from long hours sitting, vehicle incidents. |

This table format does more than just list dangers; it helps you prioritise. A potential trench collapse on a construction site poses a far greater immediate risk than a disorganised storeroom, so it naturally gets top priority. By categorising risks based on both their likelihood and the severity of potential harm, you can focus your resources where they will have the most significant impact.

This documented plan becomes the foundation for building robust, practical workplace safety procedures that your team will understand, respect, and, most importantly, follow.

Writing Procedures People Actually Want To Follow

Let's be honest: the most detailed, legally sound safety manual is worthless if it's just gathering dust on a shelf. The real goal isn't simply to have workplace safety procedures, but to create guidelines that your team understands and follows naturally, without needing constant reminders. The best procedures feel less like strict rules and more like shared agreements on the smartest, safest way to get the job done. If your current safety manual reads like a dense legal text, it’s probably not hitting the mark.

Often, this problem starts because procedures are written in an office, disconnected from the realities of the job. They don't account for the daily pressures, the common shortcuts, or the informal workarounds that are part of any real-world role. To fix this, you need to co-create these procedures with the very people who use them every day.

From Compliance to Collaboration

Instead of handing down a finished document for your team to sign off on, invite your frontline workers into the writing process. Your experienced machine operators, construction crew leaders, and warehouse staff are your true subject matter experts. They know what actually works, what doesn't, and why the 'official' method might be impractical or even less safe in certain scenarios. Involving them isn't just a courtesy; it's how you tap into a priceless well of practical knowledge.

A fantastic way to begin is by workshopping a draft procedure with a small team. Ask them to walk you through the task on the floor, pointing out where the written steps match what really happens and where they differ. Try asking questions like:

- "Does this instruction still make sense when you're under pressure or in a rush?"

- "Can we say this in a simpler way?"

- "What's missing here that could lead to a mistake or confusion?"

This collaborative method builds a sense of ownership. When workers see their own language and feedback in the final document, it becomes their procedure, not just a rule from management. This buy-in is far more effective than any enforcement measure you could dream up.

Clarity, Visuals, and Simplicity

How you present the information is just as crucial as the information itself. People rarely read large blocks of text, especially in a busy or potentially hazardous environment. Good workplace safety procedures are designed to be understood at a glance.

Here are a few tips to make your procedures more user-friendly:

- Use simple language: Swap out jargon and formal terms for clear, direct words. Instead of "personnel must egress via the designated route," just say "use this exit in an emergency."

- Embrace visuals: A picture is worth a thousand words. Use photos, simple diagrams, and flowcharts. An image showing the correct posture for lifting a box is much better than a paragraph describing it.

- Use checklists: For tasks with multiple steps, a simple checklist is easy to follow and ensures nothing gets missed. This is perfect for pre-start equipment checks or end-of-day shutdown routines.

Official resources are also a great place to start. The screenshot below is from the WorkSafe NZ website, an essential resource for any business in New Zealand.

This site is organised by industry and topic, giving you an excellent starting point for understanding the specific hazards and control measures relevant to your operations. Checking their guidance before you start writing ensures your procedures align with national standards. When you combine this official advice with your team's direct input, you create something that is both compliant and genuinely practical.

Training That Changes Behaviour, Not Just Ticks Boxes

Let’s be honest, we've all sat through those mind-numbing PowerPoint sessions that everyone endures but no one remembers. When it comes to workplace safety procedures, the goal isn’t just ticking a box on a compliance form. The real win is when your team absorbs safety principles so deeply that following them becomes second nature, especially when the pressure is on. This means creating training that actually connects with people and fits the reality of your workplace.

The best training makes safety personal and practical. It’s less about memorising rules and more about understanding the ‘why’ behind them. When a new person starts, their induction shouldn't be a tidal wave of information. It should be a guided tour of the most critical risks they'll face in their first few weeks. Top NZ employers do this by breaking down training into smaller, role-specific chunks that build over time. This approach avoids overwhelming new hires and helps the important stuff actually stick.

Crafting Training That Resonates

One of the surest ways to make training sink in is to make it interactive. We learn best by doing, not just by listening. Instead of just talking about how to use a fire extinguisher, run a live demo where your team can actually practice putting out a small, controlled fire. Rather than a lecture on safe lifting, hold a hands-on workshop where staff can practise proper techniques with the real objects they handle every day.

Consider these practical methods to make your training more engaging:

- Scenario-Based Learning: Put your team into realistic workplace situations. You could simulate a small chemical spill or a vehicle breakdown in a busy yard and get them to work together to find the safest way forward.

- Peer-to-Peer Mentoring: Pair up your new starters with experienced, safety-minded veterans. This ‘buddy system’ allows for learning on the job and makes it easier for a new person to ask questions they might be too shy to ask in a formal group setting.

- Gamification: A bit of friendly competition can go a long way. Try a safety quiz with a small prize for the winners, or a ‘hazard hunt’ where teams compete to spot the most potential risks in a specific area.

Measuring What Matters: Behavioural Change

So, how do you know if your training is actually working? The true measure of success isn't a perfect score on a quiz right after the session; it's a noticeable shift in how people act on the job. You should be observing actions on the floor, not just tracking completion rates. Are people consistently wearing their PPE without being told? Are more near-misses being reported because staff feel safe enough to speak up? These are the real signs of a healthy safety culture.

To see how effective your training is, you need to watch and listen. Post-training surveys are fine, but informal chats a few weeks later can tell you so much more. Ask questions like, "What was the most useful thing you learned?" or "Have you had a chance to use any of the techniques we talked about?" This kind of feedback is invaluable. For more ideas on building a proactive safety environment, take a look at our comprehensive health and safety blog. It’s this focus on continuous improvement, tailored to different roles and skill levels, that keeps safety front of mind without it ever feeling stale.

Communication Systems That Work When You Need Them

A dusty notice board in the breakroom and the occasional all-staff email just don’t cut it anymore for safety communication. In a modern work environment, especially one with teams spread out across New Zealand, your way of sharing critical information needs to be as strong as your physical safety guards. Truly effective workplace safety procedures depend on communication systems that get the right message to the right people, exactly when it matters most.

Think about a roading contractor with crews scattered across a large rural area. An urgent weather warning or a sudden road closure requires immediate action. An email sent from the main office might not be seen for hours. This is where a system that pushes instant notifications to rugged, vehicle-mounted or handheld two-way radios becomes invaluable. It’s not just about convenience; it’s about providing a reliable channel that works even when mobile phone reception is patchy or non-existent.

Establishing Clear Reporting Channels

One of the biggest hurdles in safety communication is creating channels that flow both ways. It's easy to push information down from management, but how do you encourage workers to send critical information back up the chain? This is particularly important for near-miss reporting. A worker who almost trips over a loose cable might not think it's worth reporting if the process is a hassle or if they fear being blamed. However, that unreported near-miss could be the precursor to a serious fall.

Successful organisations make reporting incredibly simple. Imagine a packhouse using a dedicated mobile app where a worker can quickly snap a photo of a hazard and send it to the safety officer with a short voice note. This removes friction and fosters the honest communication you need to prevent bigger problems. It shifts the culture from one of "covering up" minor issues to one of proactive, shared responsibility. The key is to ensure these reports are acknowledged and acted upon, closing the feedback loop and showing your team that their input is valued.

Emergency Notifications That Perform Under Pressure

When an emergency strikes, every second counts. Your communication system must be resilient and dependable. For instance, think about the increasing risk of events like wildfires impacting air quality. A system that can broadcast an alert to all connected devices—from digital displays in a factory to portable radios in the field—ensures everyone gets the warning at the same time. This is where planning for specific scenarios is crucial.

During a wildfire smoke event, communication must be clear about immediate actions, such as where to find N95 respirators or if operations need to be moved or stopped. These systems are an investment in your people's safety. The aim is to avoid information overload during normal operations but guarantee that when a critical alert is sent, it cuts through the noise and commands immediate attention. This reliability is the hallmark of a communication strategy that truly supports your workplace safety procedures, protecting your people when they are most vulnerable.

Measuring What Really Matters For Safety Success

If your main safety metric is just the number of injuries, you're essentially waiting for something to go wrong before you act. While tracking incidents is certainly necessary, it's what we call a lagging indicator—it only tells you about past failures. Progressive New Zealand businesses are now shifting their focus towards leading indicators, which are forward-looking measures that help you spot problems before they turn into accidents. It’s all about measuring what’s going right and building on that success.

Think of it like driving a car. Lagging indicators are like looking in your rearview mirror to see the wreckage behind you. Leading indicators, on the other hand, are like keeping your eyes on the road ahead, scanning for potential hazards, and adjusting your speed accordingly. Effective workplace safety procedures are always built on this forward-looking approach.

Beyond the Injury Rate: What to Measure

Moving past simple injury statistics means getting creative and measuring the things that truly reflect your safety culture. Instead of only counting incidents, the most successful safety managers I’ve spoken with track metrics that show genuine worker engagement and how effective their systems are. This approach gives them a much richer, more accurate picture of their workplace's health.

Here are a few powerful leading indicators you can start tracking:

- Near-Miss Reporting: How many near-misses are reported each month? A high number here isn't a bad sign; it actually points to a healthy culture where workers feel safe enough to report minor issues without fear of blame.

- Safety Observations: How often do managers or safety champions carry out informal safety walks and talks? Tracking the number of these positive interactions is a great way to measure proactive engagement.

- Procedure Audits: Don't just check if procedures exist on paper. Audit how well they are actually being followed. A simple audit could involve observing a specific task and noting how closely the actions line up with the written procedure.

- Training Effectiveness: Instead of just tracking who attended a training session, follow up a few weeks later. Use short quizzes or practical observations to see if the knowledge has stuck and is being applied on the job.

This kind of data gives you real insights you can actually do something with. For example, if you notice that near-miss reports for a specific area have dropped to zero, it might not mean it’s suddenly become the safest spot. It could mean your team has stopped reporting. That’s a red flag that calls for a conversation, not a celebration.

Turning Data into Actionable Improvements

Gathering data is only half the battle; the real work is in what you do with it. Thankfully, the overall trend for workplace fatalities in New Zealand has shown a decline, falling by about 35% over the last decade. However, the fact that preventable deaths still happen shows just how vital it is to use data to strengthen our workplace safety procedures. You can explore a summary of these national trends from WorkSafe NZ to better understand the ongoing fatality risks.

Presenting this data in a way that motivates your team is crucial. A complex spreadsheet won't inspire anyone. Try using simple, visual dashboards that everyone can understand at a glance. A chart showing a rising trend in completed safety observations is much more powerful than a raw number. Use this information in your team meetings to celebrate wins, like a month with a high number of reported (and fixed) hazards, and to discuss areas for improvement together. This transparent approach builds trust and reinforces that safety is a shared responsibility. This is especially critical when managing risks on the road; for more on this, check out our guide to applying road safety within a workplace.

Your Practical Implementation Roadmap

Turning plans into action is where the rubber meets the road in creating a safer workplace. It can feel like a massive job, but you don't need to tackle everything at once. A phased approach, where you focus on the most critical elements first, makes putting new workplace safety procedures in place much more manageable and effective. It's all about building positive momentum, not overwhelming your team.

Setting Realistic Timelines and Milestones

One of the most common pitfalls I see is setting an aggressive, unrealistic deadline for a complete safety overhaul. This almost always leads to burnout and a lot of half-finished initiatives. A much better way is to break the process down into achievable chunks. Think about what you can realistically accomplish over a 90-day period.

-

First 30 Days: Laying the Groundwork. Your initial focus should be on building a solid foundation. This is the time to carry out those collaborative risk assessments we discussed earlier and to form a dedicated safety committee with people from all parts of the business. The aim here isn't to solve every single problem. Instead, identify the top three to five highest-priority hazards and get everyone aligned. It’s also the perfect moment to look at your communication channels—are they truly up to the task in an emergency?

-

Next 30 Days: Drafting and Documenting. With your priorities clear, use this month to draft the core procedures. It’s crucial to work with the teams who will actually be using them. This ensures the language is simple and the steps are practical for day-to-day work. A key milestone for this period is to have the first draft of your most critical procedures—like your emergency response plan or how to handle hazardous substances—ready for the safety committee to review.

-

Final 30 Days: Training and Launch. This final phase is all about rolling out the new procedures and giving your people hands-on training. Please don't just email out a PDF and hope for the best. Hold interactive sessions where staff can ask questions, run through scenarios, and practise new skills. The main goal here is to have all relevant staff fully trained on the initial set of high-priority safety procedures.

Budgeting for Safety Success

Improving safety doesn't have to break the bank, but it does require some smart investment. Your budget should directly reflect the priorities you uncovered during your risk assessment. For a small business, this might mean allocating funds for high-quality PPE and setting aside paid time for staff to join in safety meetings. For a larger operation, it could involve investing in a robust communication system or bringing in a consultant for specialised training.

A practical way to think about spending is to categorise it:

- Essential Compliance: These are the non-negotiables. Think machine guarding, legally required training courses, and fully-stocked first aid kits.

- High-Impact Improvements: These are investments that give you the biggest safety bang for your buck. This could be upgrading to a reliable two-way radio system for your remote teams or installing better ventilation in a workshop.

- Continuous Improvement: This covers ongoing costs like refresher training, time for the safety committee to meet, and software for tracking incidents and inspections.

This structured plan turns a vague goal into a clear path forward. Effective workplace safety procedures are built methodically, not all at once. By focusing on prioritised steps, you can create meaningful, lasting change.

To ensure your teams stay connected, especially in some of New Zealand's tough environments, reliable communication is essential. You can find out how Mobile Systems Limited provides robust communication solutions that form the backbone of any strong safety plan.