Communications technology in New Zealand's Oil & Gas Industries

In the high-stakes world of New Zealand's oil and gas sector, a communication breakdown isn't just an inconvenience—it's a critical safety event. Reliable communications technology in New Zealand's oil and gas operations is the essential lifeline connecting offshore platforms, remote exploration sites, and onshore support teams. It’s the very bedrock of safety, efficiency, and operational integrity.

Why Communication Is a Lifeline in NZ's Oil and Gas Sector

Think about your current system. Can it guarantee a clear, instant connection from an offshore platform battling a Cook Strait storm back to your onshore command centre? For workers deep in the rugged Taranaki Basin or at isolated inland wellheads, is their communication device a tool of confidence or a point of failure?

In this demanding industry, communication isn't just an IT overhead; it's a core component of your health and safety framework and a major driver of productivity. Every single task, from coordinating complex drilling operations to managing an emergency response, hinges on the ability to transmit information clearly and without delay.

The Unforgiving NZ Environment

New Zealand's oil and gas operations face a unique set of challenges that push standard communication devices well past their limits. These environments demand technology that is not just functional but exceptionally resilient.

- Extreme Weather: Teams regularly work through punishing high winds, corrosive salt spray, and heavy rain, conditions that can quickly compromise less durable equipment.

- Geographic Isolation: Many sites, both onshore and offshore, are miles away from any public cellular networks, making independent, self-sufficient communication systems an absolute necessity.

- High-Noise Zones: The constant hum and clatter of machinery on rigs and in processing plants can make clear audio transmission impossible without specialised noise-cancelling technology.

- Hazardous Conditions: The presence of flammable gases and materials requires intrinsically safe devices. These are specially certified not to produce sparks—a non-negotiable for site safety. You can learn more about the unique communication challenges in the gas and mining industries.

More Than Just a Call: The Operational Backbone

For every engineer on a remote wellhead or technician on a sprawling processing plant, a dependable communication link is their lifeline. It underpins every safe and productive action they take.

A modern system goes far beyond a simple voice call, providing:

- Instantaneous Coordination: Ensuring complex, multi-team tasks are executed with pinpoint precision.

- Emergency Response: Giving teams a reliable channel to summon help and manage incidents effectively.

- Lone Worker Protection: Offering peace of mind through GPS tracking and automated 'man down' alerts.

- Operational Efficiency: Slashing downtime by enabling quick problem-solving between field crews and technical support.

Core Communication Technologies for NZ's Energy Sector

To keep things safe and running smoothly in New Zealand’s tough oil and gas sector, you need the right tools for the job. Getting a handle on the main communication technologies is the first step to building a solid network that looks after your people and your assets. Let's break down the essential systems that keep teams connected, from onshore processing plants to remote offshore rigs.

These aren't just gadgets; they're the nuts and bolts of a modern, safety-first operation. Each bit of kit serves a specific purpose, designed to tackle the unique challenges thrown up by the environment and the work itself.

UHF/VHF Two-Way Radio Networks

Think of your classic UHF (Ultra High Frequency) and VHF (Very High Frequency) two-way radio networks as the absolute workhorses of on-site comms. For decades, brands like Tait, Motorola, and Hytera have provided that tough, instant push-to-talk capability that’s non-negotiable for coordinating teams in a set area, whether it's a refinery, a drilling site, or an offshore platform.

Their biggest advantage is their INDEPENDENCE. These radio networks don't lean on public cellular infrastructure, which can be spotty in rural Taranaki or simply non-existent out on the water. This makes them incredibly reliable during an emergency when public networks might get jammed or fail completely. A private radio network is your own self-contained ecosystem that you control.

Push-to-Talk over Cellular (PoC)

But what happens when your operations stretch beyond a single site? This is where Push-to-Talk over Cellular (PoC) steps in. PoC gear gives you the same instant, walkie-talkie style chat as traditional two-way radio, but it cleverly uses New Zealand’s cellular data networks to connect everyone up.

This brings some serious benefits to the table:

- Nationwide Coverage: A manager in Auckland can instantly talk to a field tech in Taranaki, as long as they both have a mobile signal.

- Minimal Infrastructure: It cuts out the need to install and look after your own radio repeaters and antennas, which saves a lot on upfront costs.

- Modern Features: PoC devices often come with GPS tracking, video streaming, and other handy data applications built-in.

The main thing to remember, though, is that it completely depends on cellular coverage. While it’s fantastic for linking up teams spread across different locations with good service, it’s not the answer for genuinely remote or offshore sites where there’s no signal.

Satellite Communications

When your operations push far beyond the reach of any cell tower, satellite communications are really the only game in town. Systems from providers like Iridium and Starlink offer a lifeline for data and voice, making sure your most remote teams are never completely cut off.

Satellite technology is the ultimate safety net. It provides a reliable channel for voice calls, data transfers, and emergency alerts, no matter how isolated the worksite is. It turns remote black spots into fully connected operational zones.

Whether it’s sending back critical telemetry data from a remote wellhead, enabling a video call with an expert back on shore, or providing the main communication link for an entire offshore platform, satellite is the bridge back to civilisation.

GPS Tracking and Lone Worker Solutions

Finally, weaving through all these technologies is the critical safety layer of GPS tracking and dedicated lone worker solutions. Under New Zealand's Health and Safety at Work Act, employers have a strict duty of care, especially for people working alone in high-risk spots. This is where technology becomes an essential tool for staying compliant.

Picture a pipeline inspector working in a remote, hilly part of the country. A modern digital radio or PoC device can be set up with features that automatically protect them:

- Man Down Alerts: A sensor detects if the worker has fallen and isn't moving, automatically triggering an alarm.

- Real-time Location Data: Supervisors can see the worker's exact location on a map, which massively cuts down response times in an emergency.

- Panic Buttons: A simple, dedicated button lets the worker call for help in an instant.

For those designing more complex networks in the oil and gas industry, it's worth exploring the benefits of reliable data transmission, like those covered in this overview of Interconnected and Independent Communication: The Superiority of Brooks’ Mesh Technology. These features aren't just nice-to-haves; they are indispensable tools for meeting your safety obligations and, most importantly, making sure every team member gets home safely.

Choosing Your Ideal Communication System

Picking the right communications tech in New Zealand's oil and gas sector isn't just an IT decision—it's a critical call for safety and operational efficiency. With lives and productivity on the line, you need to be sure the system you choose is the right tool for the job.

Get it wrong, and you're looking at dangerous coverage gaps, compliance headaches, and gear that fails when you need it most. Let's break down the core choices to make sure your investment hits the mark, keeps your team safe, and is built to last.

Digital Versus Analogue Two-Way Radio

For years, analogue radios were the go-to. They were simple and did the job. But today’s Digital Mobile Radio (DMR) systems—from trusted names like Motorola, Tait, and Hytera—are a massive step up in every way that matters on a rig, platform, or remote site.

While analogue might seem cheaper at first glance, the real-world benefits of DMR are game-changing for the oil and gas industry:

- Crystal-Clear Audio: DMR radios use smart algorithms to cut out background noise. That means a worker in a deafening engine room or on a windswept Taranaki platform can be heard perfectly, slashing the risk of costly misunderstandings.

- More Than Just Voice: Digital radios handle data as well as voice. This opens the door to powerful tools like live GPS tracking, sending quick text messages for updates, and even remote monitoring of equipment.

- Batteries That Last the Shift: DMR is simply more power-efficient. You can expect up to 40% longer battery life compared to similar analogue radios. That’s crucial for long, demanding shifts where finding a charger isn't an option.

- Stronger, More Reliable Coverage: Digital signals stay strong right to the edge of their range. You get clear audio without the static, fading, and crackle that plagues analogue radios as the signal weakens.

Push-to-Talk over Cellular (PoC) vs Traditional UHF/VHF

Next up is a big decision: do you build your own private radio network or leverage New Zealand's cellular networks?

Push-to-Talk over Cellular (PoC) gives you the instant, one-to-many communication of a two-way radio but runs over 3G, 4G, and 5G. It’s perfect for teams that are spread out, easily connecting a head office in Wellington with a fleet of vehicles servicing sites across the country. It’s a subscription-based service, so you avoid the big upfront cost of building your own repeater towers.

On the other hand, traditional UHF/VHF radios create your own private, self-contained network. This is the gold standard for site-specific operations, especially offshore or in remote areas where there’s zero cell reception. You own the infrastructure, which means your communication lines are GUARANTEED to work, even if public networks go down in an emergency.

When mapping out comms for a remote site, checking the terrain is non-negotiable. A good Line of Sight tool can show you exactly where hills or other obstacles might block your signal, helping you plan repeater placement perfectly.

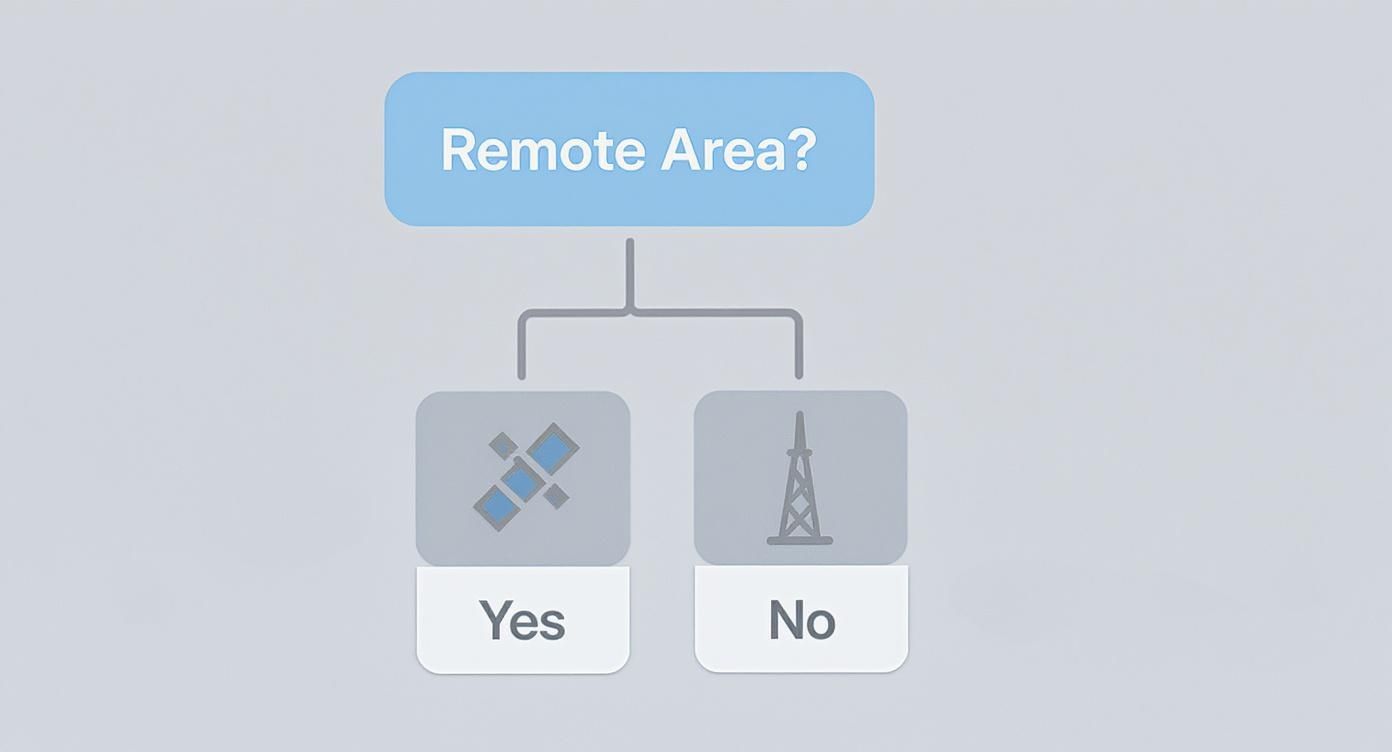

This simple flowchart breaks down the first question you should always ask: where is my team working?

As you can see, your location is the biggest factor. If you're outside cell coverage, satellite becomes your lifeline. For a deeper look at how this works, check out our guide on satellite internet options in New Zealand.

By thinking carefully about your operational footprint—is it a single site, spread across the country, or miles offshore?—you can confidently choose the communication backbone that will best support your team.

Technology Comparison for NZ Oil and Gas Operations

To make the decision even clearer, here’s a side-by-side look at how these technologies stack up for the specific demands of New Zealand's oil and gas operations.

| Feature | Digital Two-Way Radio (DMR) | Push-to-Talk over Cellular (PoC) | Satellite Communicators (Iridium/Inmarsat) |

|---|---|---|---|

| Best For | Site-specific operations (rigs, plants), high-noise areas, remote sites without cell service | Geographically dispersed teams, logistics, nationwide fleet management | Offshore platforms, remote exploration, emergency backup where all else fails |

| Coverage | Limited by private repeater infrastructure; excellent for defined areas. | Nationwide, anywhere with 3G/4G/5G cellular coverage. | 100% global coverage, including at sea and in the most isolated land areas. |

| Infrastructure Cost | High initial capital investment for repeaters and licensing. | Low initial cost; relies on existing cellular networks. | Moderate to high hardware cost per device. |

| Ongoing Cost | Low; mainly maintenance and Radio Spectrum Management (RSM) licence fees. | Monthly subscription fee per device. | Monthly or annual subscription plans based on data/voice usage. |

| Key Advantage | TOTAL network control and reliability, independent of public infrastructure. | VAST coverage area without needing to build your own network. | GUARANTEED connectivity anywhere on Earth, critical for ultimate remote safety. |

| Main Limitation | Range is limited to your infrastructure footprint. | Dependent on public cellular networks; no service in remote or offshore locations. | Higher latency and data costs compared to terrestrial options. |

Ultimately, the right choice depends entirely on your operational reality. A Taranaki-based onshore facility will have vastly different needs than an exploration vessel in the Great South Basin. By understanding these core differences, you can equip your teams with a communication system that is reliable, safe, and fit for purpose.

NZ Compliance and Safety Requirements

In the high-stakes world of New Zealand's oil and gas sector, compliance is much more than a box-ticking exercise. It’s the very foundation of a safe, productive, and legally sound worksite. The communications technology in New Zealand's oil and gas operations has to do more than just connect teams—it must actively protect them and meet some of the country’s most stringent regulations.

Getting this wrong isn't an option. It can lead to serious incidents, hefty penalties, and downtime that no operation can afford.

Operating safely means building your systems around the Health and Safety at Work Act 2015. This legislation places a clear duty of care on employers to manage risks, and for the energy industry, that has major implications for how you handle communications—especially for staff in hazardous zones or working alone.

Protecting Your Lone Workers

The legislation doesn't mince words when it comes to protecting lone workers. If you have a technician inspecting a remote pipeline or an engineer working solo in a sprawling processing plant, you are REQUIRED to have reliable procedures to monitor their well-being. This is where modern communication devices become critical compliance tools.

For any lone worker, these features are simply non-negotiable:

- Real-time GPS Tracking: Knowing the exact location of a team member is the first step in any emergency. It’s absolutely crucial for dispatching help quickly and accurately when every second counts.

- 'Man Down' and No-Motion Alerts: Today’s digital radios from brands like Motorola and Tait aren't just for talking. They can be programmed with automated safety alerts that trigger if the device tilts past a certain angle (indicating a fall) or stays motionless for too long, sending an immediate signal to a supervisor.

- Dedicated Emergency Buttons: A single, easy-to-press panic button allows a worker to summon help instantly without fumbling through menus or trying to dial a number under pressure.

These aren't just 'nice-to-have' extras; they are FUNDAMENTAL parts of a modern, compliant health and safety system.

Durability and Hardware Resilience

The punishing physical demands of an oil and gas site mean consumer-grade gear just won't cut it. Your hardware has to be built to survive, and that’s where Ingress Protection (IP) ratings become so important.

An IP rating gives you a clear, standardised measure of how resistant a device is to solids (like dust and mud) and liquids (like water and oil). For offshore rigs or notoriously wet onshore environments, a rating of IP67 or higher is the bare minimum. This certification means the device is completely dust-tight and can survive being submerged in one metre of water for 30 minutes without failing.

This level of toughness ensures your investment is protected from corrosive saltwater, abrasive drilling mud, heavy rain, and the inevitable drops, guaranteeing your communication lifeline stays open.

Acoustic Safety in High-Noise Environments

Engine rooms, drilling floors, and processing plants generate extreme noise levels that can easily damage hearing and make standard communication impossible. WorkSafe New Zealand has very clear guidelines on managing workplace noise exposure.

This is where specialised headsets and remote speaker microphones become vital. Brands like Sensear produce smart headsets that actively suppress dangerous background noise while letting crucial voice commands come through crystal clear. This technology allows your teams to communicate effectively without risking their long-term hearing health.

Intrinsically Safe (IS) Requirements

Perhaps the most critical safety specification in oil and gas is the need for Intrinsically Safe (IS) equipment. In any area where flammable gases, vapours, or dust might be present, a standard electronic device is a potential ignition source—a deadly risk.

IS-rated radios are meticulously engineered from the ground up to prevent any possibility of creating a spark. Using non-certified equipment in these zones is a major safety breach. To understand the specifics, have a look at our guide on what makes a radio intrinsically safe.

Overcoming Common Communication Challenges in the Field

Book smarts will only get you so far. With over two decades in the trenches, we’ve seen just about every communication headache that can pop up on New Zealand’s oil and gas sites. What works on paper often falls apart in the real world, and that’s where hard-won experience really counts.

We spend a lot of time helping clients fix common but incredibly frustrating issues. Think trying to get seamless coverage across a sprawling, hilly onshore site, or maintaining a clear signal inside a steel-clad processing plant where radio waves just don't want to go. These aren't just small annoyances; they're genuine operational risks that need a proper solution.

Solving Coverage Black Spots

One of the most common complaints we hear about is the dreaded "black spot"—those dead zones where comms just vanish. In a high-risk environment, that’s a complete non-starter. The fix is rarely a single piece of kit; it usually takes a more layered approach.

For big onshore sites, it starts with a professional coverage survey. From there, we can strategically place radio repeaters. These devices act like a signal booster, effectively bending the radio waves over hills and around buildings to create a solid blanket of coverage.

And what about inside buildings or vehicles where the cell signal is weak? If you're relying on PoC devices, a Cel-Fi cellular booster can be a lifesaver. It grabs whatever faint signal it can find outside and powerfully rebroadcasts it indoors.

Avoiding Common Purchasing Mistakes

We also see a lot of money wasted on the wrong gear. A classic mistake is buying consumer-grade radios from a big department store for an industrial job. They simply can't handle the vibration, moisture, and general rough-and-tumble of an oil and gas site, leading to early failures that put your team at risk.

Another thing that often gets overlooked is proper battery management. A radio with a flat battery is just dead weight. Professional systems from brands like Motorola and Tait are built for this, with high-capacity batteries and smart multi-bay chargers that guarantee every radio is ready for a full shift.

A thoughtfully designed communication system does more than connect people; it anticipates and prevents problems. It is an investment in unwavering reliability, ensuring your operations never stop because of a preventable communication failure.

The story of communications technology in New Zealand's oil and gas industry has always been about solving these real-world problems. Back in the 1980s, local innovators like Tait Communications were crucial in developing the tough mobile radio systems the energy sector needed. They brought in trunked and digital radio, giving sites the reliable, private networks required for coordinating remote teams and handling critical safety comms. You can read more about this great Kiwi innovation story on the Tait Communications website.

By working with an experienced provider, you're tapping into this deep industry knowledge. It’s the best way to ensure you get a system that’s not just powerful, but perfectly matched to the real demands of your operation.

Why Choose Mobile Systems Limited?

Choosing the right communications gear for an oil and gas operation isn’t like buying off the shelf. It’s about finding a long-term partner who’s genuinely invested in keeping your crew safe and your site running smoothly. This isn’t just a transaction; it’s a commitment to making sure the system works flawlessly from day one and for its entire life.

In this industry, generic solutions from suppliers who don't live and breathe this stuff just won't cut it. You need a team on the ground that gets the terrain, the regulations, and the immense pressure your people are under every single day.

A Genuinely Local, End-to-End Solution

We are a 100% NZ owned and operated company, based right here in Mt Maunganui. For nearly two decades, Mobile Systems has been the go-to for Kiwi businesses working in high-stakes industries. We don't just ship boxes; we build and deliver complete communication solutions designed around exactly what you need.

Our entire service is built on a deep understanding of what actually works out in the field:

- Expert Consultation: It all starts with a conversation. We listen to understand your specific headaches, whether it’s a dead zone in a remote valley or a need for better lone worker safety protocols.

- Custom Coverage Planning: Our team designs systems that give you solid coverage precisely where you need it, using professional mapping tools and on-site analysis to get it right.

- RSM Licensing Sorted: We’ll handle all the complex paperwork with Radio Spectrum Management to make sure your network is fully licensed and compliant from the get-go.

- Professional On-site Installation: Our mobile fleet of technicians comes to you. We make sure every piece of hardware is installed, programmed, and field-tested to the highest standard.

Beyond the Sale—Our Commitment to You

The true test of any partnership shows up long after the initial setup. That’s why we offer managed servicing and proactive maintenance plans—our goal is to catch potential problems and prevent downtime before it ever happens. This ongoing support makes sure your investment keeps delivering and, most importantly, keeps your teams safe and connected.

Reliable radio technology has been a constant throughout New Zealand’s industrial history. It’s been a backbone of the oil sector since the early 20th century, with VHF radio becoming the standard for two-way comms back in the 1950s. This long history highlights just how critical it is to choose an expert partner for today's advanced systems. You can read more about the fascinating history of radiocommunications in New Zealand on the RSM website.

When you work with Mobile Systems, you’re choosing a trusted, dependable Kiwi team that’s in it for the long haul.

Let's Talk About Your Needs

Ready to build a communications system that boosts safety, improves efficiency, and gives you total peace of mind?

Our team of New Zealand-based specialists is here to help. We can provide personalised device recommendations, a no-obligation quote, or even arrange a demo so you can see the technology in action.

Contact Mobile Systems today to speak to a communications expert.

Frequently Asked Questions

When it comes to outfitting your oil and gas operation with the right comms gear, a few key questions always come up. We hear them from operational managers and procurement staff across New Zealand, so we've put together some straight-up answers based on what we see working in the field every day.

What is the best communication setup for an offshore platform?

There’s no single piece of kit that does it all. For an offshore platform, you're looking at a layered approach. Think of it as building a system with multiple safety nets – you need redundancy and absolute reliability for both on-deck coordination and the vital link back to the mainland.

A solid, field-proven configuration typically includes:

- Intrinsically Safe UHF/VHF Radios: For the day-to-day chatter between teams on deck, you need rugged, certified radios. Brands like Motorola, Tait, Hytera or Entel are the gold standard here, built to provide clear, instant comms in hazardous zones where a spark could be catastrophic.

- Marine VHF Radios: This isn't just a good idea; it's a regulatory must-have. These are for communicating directly with support vessels, supply boats, and any other marine traffic nearby.

- Satellite System: This is your lifeline to the outside world. A high-speed data connection from a service like Starlink or an ultra-reliable voice link from Iridium provides the essential data and backup voice channel to your onshore operations centre.

This multi-layered setup means that if one system falters, you have others to fall back on. It ensures your crew stays connected to each other and to mission control, no matter what.

How can we guarantee radio coverage across a large onshore site?

Getting 100% reliable radio coverage across a sprawling onshore site, especially with the hilly terrain we see around Taranaki, is a science, not guesswork. Just buying more powerful radios is a common mistake and rarely solves the problem.

The professional way to tackle this starts with a comprehensive coverage survey. Our technicians come to your site with specialised gear to literally map out your operational area. We pinpoint every signal weakness, dead zone, or "black spot" caused by hills, large metal structures, or other interference.

Once we have that data, we can strategically place radio repeaters. These devices act like signal boosters—they catch the radio signal, amplify it, and rebroadcast it into the weak areas. A well-designed repeater network creates a seamless blanket of crystal-clear communication, making sure no worker is ever out of touch, no matter where they are on site.

Are digital radios worth the investment over analogue in noisy environments?

YES, ABSOLUTELY. In the kind of high-noise environments you find on a rig floor or in an engine room, upgrading from analogue to Digital Mobile Radio (DMR) is one of the single biggest improvements you can make to safety and efficiency.

The difference is night and day. DMR tech has some serious advantages that make it a far better choice for your industry:

- Built-in Noise Cancellation: This is the game-changer. DMR radios use smart software to filter out the constant drone of machinery, so only the user's voice gets transmitted. Instructions are heard clearly the first time, every time, which drastically reduces errors.

- Longer Battery Life: Digital radios are just more power-efficient. You can expect a DMR battery to comfortably last a full 12-hour shift, whereas an older analogue radio might struggle.

- More Than Just Voice: DMR isn't just about talking. It opens the door to critical safety features like GPS tracking to locate your team, text messaging for quiet or non-urgent updates, and even remote monitoring. It’s the backbone of a modern, connected, and safe worksite.